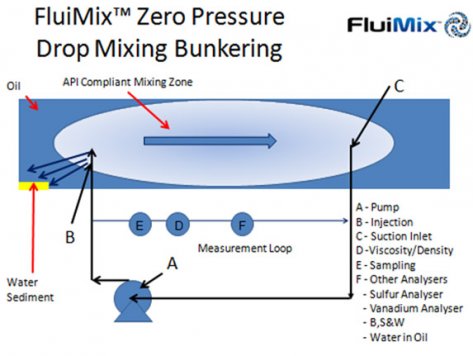

FluiMix

FluiMix™ is a zero pressure drop inline mixer that is ideal for any bunker station or barge operation. It provides inline mixing to ensure that fuel is fully mixed and complies to API 8.2, D4177, ISO 3171, and ISO 13789 (as demanded by ISO 8217).

FluiMix™ is an ideal alternative to static mixers for a terminal operator because

- FluiMix™ can process any viscosity fuel for any process flow rate

- The same FluiMix™ blender can process 10 MT/hour to 1000 MT/hour with fuel viscosities of 30cSt to 1500 cSt

- FluiMix™ reduces energy consumption, your carbon footprint and wear on the main transfer pumps by 25% - 50% for higher viscosity fuels.

FluiMix™ is an extremely cost effective way to de-bottle neck, whilst improving quality assurance. It is a short lead time product that will quickly increase capacity, profitability and enable processing of low cost higher viscosity fuels.

FluiMix™ can also be hot-tapped and retro-fitted to an existing blending facility without the need for any process shut down.

FluiMix™ is a fast loop mixing system that provides ideal conditions for a far wider range of analysers than is possible with traditional blending solutions. A barge or terminal operator can now measure critical properties either in the feed stock or finished fuel oil and this makes compliance to ISO 13789 far easier by using:

- Online Viscosity Measurement

- Online Fiscal Density Measurement

- Online Vanadium Analyzers

- Online Sulfur Analyzers

- Online Water in Oil Analyzers

- Online Salt Analyzers

- MARPOL Compliant Samplings

- ISO 13789 Compliant Samplings

.