FluiDense

Accurate density measurement is a function of the density measurement technology, the degree of flow conditioning at the measurement point and the accuracy of any temperature compensation used to normalize the density reading to the desired reference temperature.

FluiDense™ Animation

FluiDense™ combines four unique technology packages that deliver enhanced accuracy and reliable density trim control:

- Dynamic Density Temperature Compensation

- FluiMix™ Compliant Mixing

- Enhanced Accuracy Measurement of Density to +/-0.00001gm/m3

- Densitometer Performance Verification - Self Diagnostic and Density Verification to enable real time quality assurance of densitometer accuracy and reliability;

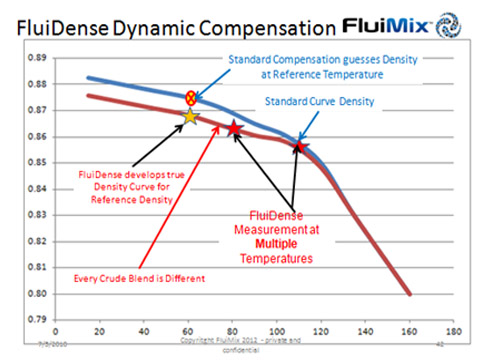

FluiDense™ Dynamic Density Temperature Compensation

The accuracy of any temperature compensation used during the oil blending process has a significant impact on the performance of the blender because:

- Crude oil blending normally occurs at process temperatures between 25 – 40 0C which is significantly higher than the reference temperature of the target density (ie 60 0F or 15 0C)

- Every crude oil has its own distinct specific relationship between density and temperature

- Refineries and producers will typically blend many different types of oil from distinctly different sources and there will be significant differences in the density/temperature profile for each oil even if the densities are similar.

Traditional Blenders measure density at the process temperature and then use a standard density/temperature calibration curve to “guestimate” the blend density to the desired reference. These standard curves rarely if ever represent the actual temperature/density relationship of the blend being processed and this phenomenon introduces significant error.

FluiDense™ measures density at multiple temperatures between the reference and the process temperatures and develops the actual temperature/density profile of the blend of oil being processed. FluiDense™ is continually retuning the temperature compensation curve over time as the feedstock fluctuates creating an extremely accurate compensation curve. FluiDense™ then controls the blend at a control temperature that is far closer to the reference temperature than the process temperature. FluiDense™ then uses this updated and true compensation curve to adjust the density to reflect the difference between the reference temperature and the control temperature.

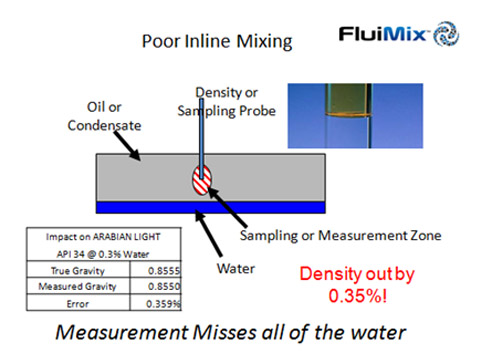

FluiMix Compliant Mixing

Oil blenders typically use mixing headers, mixing valves and static mixers to blend the two streams of crude together. These mixers are rarely sized to deliver sufficient mixing to ensure the water that is always present in the oil is fully mixed across the pipeline flow. Without adequate mixing, the water will flow under the densitometer and introduce an intrinsic and varying error density reading to any blender. This error can be anywhere from 0.1 – 0.4% depending on the ever changing level of background water content in the oil feedstocks.

All FluiDense™ systems are provided with a FluiMix™ inline mixer that is guaranteed to

- Provide sufficient inline mixing that complies to API 8.2, ISO 3171 and D4177 for the whole operating window of the blender;

- Any density measurement is guaranteed to include all the entrained water to +/-0.025% of the true water content in the process stream.

FluiMix™ eliminates any impact that varying water concentration, flow rates and feedstock temperature and viscosity has on the density measurement.

FluiMix™ is a zero pressure drop mixing system that has limitless turn down and can mix any viscosity fluid without increasing pressure drop and reducing the facilities capacity.

FluiMix™ is an ideal mixing system for any oil blender because it has a far wider operating window than traditional mixing headers, static mixers or mixing valves that have very limited operating windows.

FluiMix™ ensures that the accuracy of the blending process is not affected by variations in feedstock or flow conditions but on the accuracy of the density measuring technology.

FluiDense™ Enhanced Accuracy Density Measurement

To insure that the FluiBlender™ operates as accurately as possible, all FluiDense™ density measurements taken with instrumentation that is UKAS certified. The performance of the density readings are to within +/-0.0001 gm/cm3 with a repeatability of 0.00002 gm/cm3

FluiDense™ Density Verification System

All analyzer technology is prone to trending and requires constant monitoring. The FluiVisc™ Density Verification System continually monitors the performance of each densitometer to ensure the integrity, accuracy and reliability of a FluiBlend™ package. This enables a FluiBlend to operate at safe blend density far closer to the final product specification than traditional blenders.

FluiDense™ is available in three formats:

FluiDense™ TD

- FluiDense™ TD has self-diagnostic capabilities that will automatically detect any drifting of the critical density measurement

- FluiDense™ TD has multiple Density and temperature measurement and real time tuning of the temperature compensation

- FluiDense™ Accuracy is Fiscal Density Accuracy with UKAS certification – all density measurements are taken to the following Fiscal Density accuracies and repeatability levels:

Accuracy +/- 0.0001 g/cc (0.3 – 1.1g/cc)

Repeatability +/- 0.00002 g/cc

FluiDense™ Dual

- FluiDense™ Dual has Dual Density and temperature measurement and real time tuning of the temperature compensation.

- FluiDense™ Dual Accuracy is Fiscal Density Accuracy with UKAS Certification - all density measurements are taken to the following Fiscal Density accuracies and repeatability levels:

Accuracy +/- 0.0001 g/cc (0.3 – 1.1g/cc)

Repeatability +/- 0.00002 g/cc

FluiDense™ Mono

- FluiDense™ Mono relies on one density temperature compensation that uses traditional fixed compensation curves. The Density Compensation does NOT change with the Feed Stocks so the Compensation is NON Dynamic in nature:

- FluiDense™ Accuracy Mono is NOT Fiscal Density standards and is not UKAS Certified:

Accuracy +/- 0.00015 g/cc (0.3 – 1.1g/cc)

Repeatability +/- 0.00002 g/cc